The Differences between Short Pulsed Fiber Laser Marker and Ordinary Fiber Laser Marker

Upload Time:

May 28, 2025

Short pulsed laser marking is particularly suitable for products that require high precision, minimal thermal damage, and intricate detailing, especially when working with sensitive or high-value materials

Differences between short pulsed fiber and ordinary fiber laser marker

Here are the key differences between short pulsed fiber laser markers and ordinary fiber laser markers, summarized in terms of working principles, application scenarios, and performance characteristics:

1. Working Principle and Pulse Characteristics

|

Feature |

Short Pulsed Fiber Laser Marker |

Ordinary Fiber Laser Marker |

|

Pulse Duration |

Extremely short pulses (typically nanoseconds (ns) or even picoseconds (ps)). |

Longer pulses (microseconds (μs) or continuous wave (CW)). |

|

Peak Power |

Extremely high peak power (up to megawatts) during each pulse. |

Lower peak power (stable output in continuous or long-pulse mode). |

|

Energy Delivery |

Energy is concentrated in short bursts. |

Energy is delivered continuously or in longer pulses. |

2. Material Processing Effects

Short Pulsed Fiber Laser Marker

- Advantages:

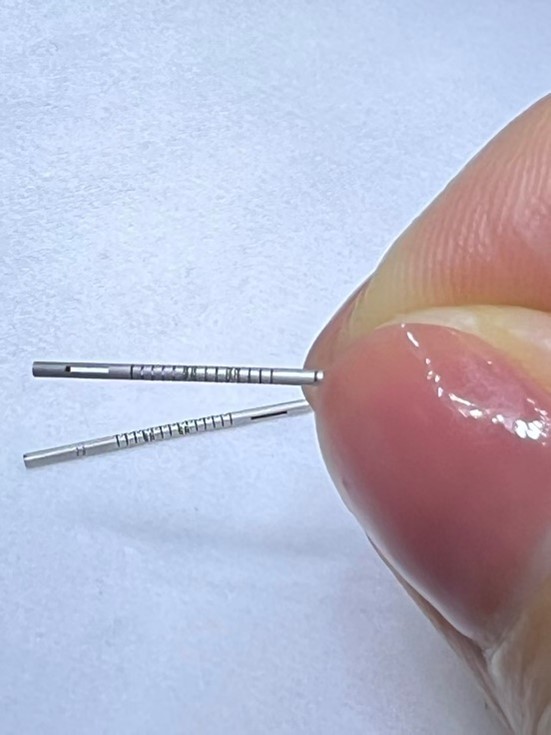

- Precision Microprocessing: Ideal for ultra-fine marking, engraving, or cutting of sensitive materials (e.g., plastics, ceramics, thin films, and delicate electronic components).

- Minimal Heat Affected Zone (HAZ): Short pulses reduce thermal damage to the material, preserving surface integrity and avoiding deformation.

- High-Quality Marking: Produces sharp, clean marks with minimal burrs or charring, even on reflective metals (e.g., aluminum, copper) or transparent materials.

- Typical Applications:

- Medical devices (stents, surgical tools), electronics (PCB marking, semiconductor packaging), jewelry, and high-precision automotive components.

Ordinary Fiber Laser Marker

- Advantages:

- High Throughput: Suitable for high-speed marking on large surfaces or bulk materials (e.g., metal parts, pipes, packaging).

- Cost-Effective for Basic Tasks: Efficient for deep engraving or annealing on metals (e.g., stainless steel, carbon steel) and some plastics.

- Typical Applications:

- Industrial part serialization, barcodes, logos on tools/equipment, and heavy-duty material processing.

3. Material Compatibility

|

Material |

Short Pulsed Fiber Laser Marker |

Ordinary Fiber Laser Marker |

|

Metals (Reflective) |

Excellent (e.g., aluminum, gold, silver) due to short-pulse absorption. |

Less effective (risk of reflection damage to the laser in CW mode). |

|

Heat-Sensitive Materials (Plastics, ceramics, glass) |

Well-suited (low heat input). |

Limited use (risk of melting or cracking). |

|

Thin Films/Coatings |

Precise ablation without damaging the substrate. |

May cause overheating and delamination. |

4. Performance and Operational Considerations

|

Aspect |

Short Pulsed Fiber Laser Marker |

Ordinary Fiber Laser Marker |

|

Marking Speed |

Moderate to high (depends on pulse repetition rate). |

High (continuous or rapid pulsing for bulk tasks). |

|

System Complexity |

More complex (requires advanced pulse control and cooling). |

Simpler (standard CW or long-pulse configurations). |

|

Cost |

Higher (due to sophisticated technology and components). |

Lower (more widely adopted for industrial basics). |

|

Maintenance |

Requires careful alignment and cooling system upkeep. |

Lower maintenance (robust for industrial environments). |

5. Key Use Case Scenarios

- Short Pulsed Fiber Laser Marker:

- When marking small, intricate parts with high precision (e.g., microscale components in aerospace or medical devices).

- When working with heat-sensitive or expensive materials where thermal damage must be avoided.

- Ordinary Fiber Laser Marker:

- When large-scale, high-speed marking is needed (e.g., labeling pallets, automotive parts, or metal fabrication).

- When deep, permanent marks (e.g., serial numbers or logos) are required on durable materials.

Summary: Core Trade-offs

- Short Pulsed Fiber Lasers prioritize precision, minimal heat impact, and versatility across materials, making them suitable for high-value, delicate applications.

- Ordinary Fiber Lasers focus on speed, cost-effectiveness, and robustness, ideal for industrial-scale, non-sensitive tasks.

Relevant News