Laser Cleaning In Industrial Applications

Upload Time:

Jul 29, 2025

The laser cleaning machine is an efficient and environmentally friendly surface cleaning equipment that uses a high-energy laser beam to remove contaminants or coatings from the surface of materials, suitable for a wide range of materials and scenarios

The laser cleaning machine is an efficient and environmentally friendly surface cleaning equipment that uses a high-energy laser beam to remove contaminants or coatings from the surface of materials, suitable for a wide range of materials and scenarios. The following are its main application areas and cleaning objects:

1. Metal materials Oxides and Rust: Remove oxide layers (such as rust) from surfaces such as steel and aluminum alloys without damaging the substrate. Oil and grease: Remove grease stains or industrial lubricants from mechanical parts, mold surfaces. Welding residue: clean up welding slag and welding spots to improve the quality of subsequent processes. Coating pretreatment: Clean the surface before spraying and plating to enhance adhesion.

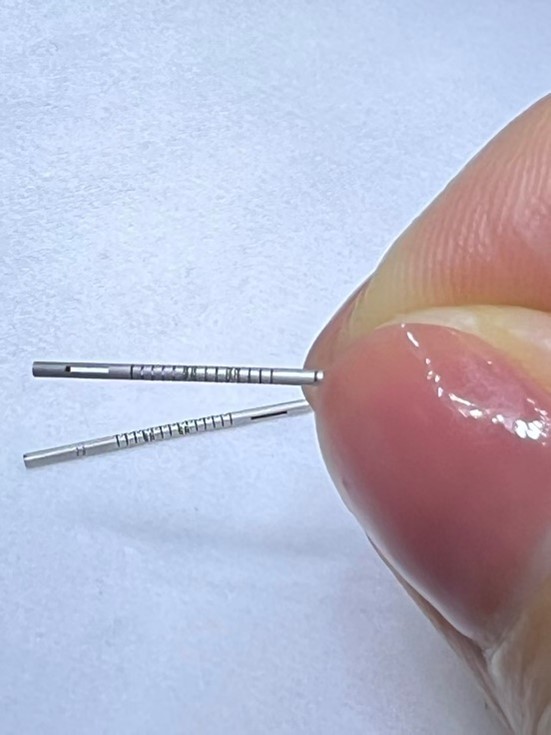

2. Cultural heritage and precision devices Cultural Relics Restoration: Safely remove dirt, pasting, or aging coatings from antiques, sculpture surfaces, avoiding mechanical damage. Precision Parts: Clean electronic components, optical lenses, precision molds, and other components that require high surface integrity.

3. Composite materials and polymer materials Rubber molds: remove mold release residues or aging layers, extending mold life. Carbon fiber: Cleans up resin residues or contaminants without affecting fiber structure.

4. Construction and stone Stone surfaces: remove stains, moss or old coatings from marble and granite. Historic buildings: Clean dust or chemically corroded layers on masonry, metal trim.

5. Electronics industry Circuit board (PCB): Remove flux and oxides to improve electrical conductivity. Semiconductor components: Cleans the surface of the wafer from particulates or organic residues.

6. Automotive & Aerospace Aircraft skin: Remove paint, oxide layer, reduce weight and check for damage. Engine components: clean up carbon deposits and oil stains to improve maintenance efficiency.

7. Other special applications Decontamination of nuclear facilities: Safe removal of radioactive contaminants. Tire molds: Efficiently remove rubber residue, reducing downtime.

Not applicable or cautionary situations:

1. Certain plastics: Materials with low melting point (e.g., PVC, ABS) may be laser ablated. 2. Highly reflective materials: such as pure copper, gold, silver, etc., need to adjust the laser parameters (such as using green lasers).

3. Transparent materials: Glass, acrylic, etc. can be difficult to clean due to laser penetration.

Advantages: Non-contact: avoids mechanical wear.

Precise and controllable: Can be cleaned locally, suitable for complex shapes. Environmentally friendly: No chemical solvents, reducing waste.

Relevant News