The Significance of Auto Focus in Laser Marking

Upload Time:

Jul 10, 2025

Auto focus technology plays a crucial role in laser marking, offering several key advantages that enhance efficiency, precision, and versatility.

Auto focus technology plays a crucial role in laser marking, offering several key advantages that enhance efficiency, precision, and versatility. Here are its primary benefits:

-

Consistent Marking

Quality

Manual focusing is prone to human error, leading to inconsistent focal positions across workpieces. Auto focus ensures the laser beam always maintains the optimal focal distance from the material surface, resulting in uniform mark clarity, depth, and edge sharpness—critical for applications like serial numbering, logos, or precision part marking. -

Increased Production

Efficiency

Auto focus eliminates the time-consuming manual adjustment process, especially in high-volume production. It rapidly adapts to workpiece variations (e.g., height differences) without operator intervention, reducing setup time and maximizing throughput. This is particularly valuable in automated assembly lines where speed and continuity are essential. -

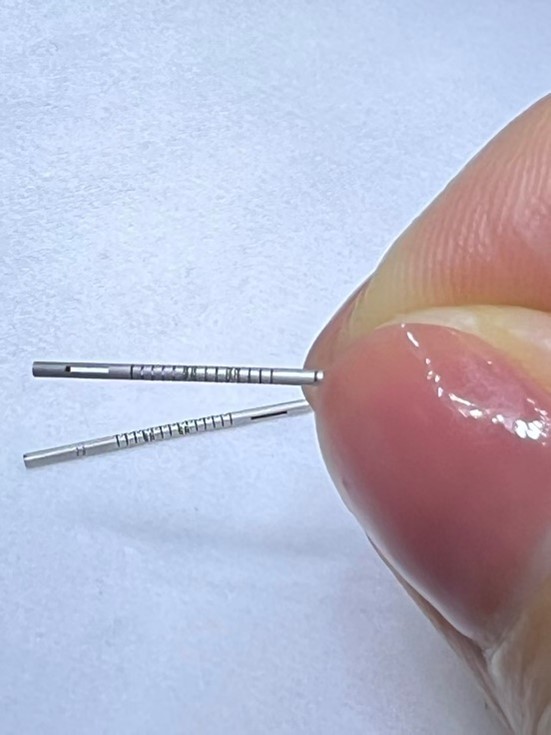

Adaptability to

Complex Workpieces

Many industrial parts have uneven surfaces, curved profiles, or varying thicknesses (e.g., metal components, plastic molds, or electronic boards). Auto focus systems (often paired with sensors like vision cameras or laser rangefinders) dynamically detect surface height changes and adjust the focal position in real time, ensuring accurate marking even on non-planar or irregularly shaped objects. -

Reduced Operator

Skill Requirements

Manual focusing demands trained operators to master precise adjustments, which increases training costs and risks errors from inexperience. Auto focus simplifies operation, allowing less skilled personnel to handle marking tasks, lowering labor costs and minimizing human-induced defects. -

Protection of

Equipment and Workpieces

A misaligned focal point can cause uneven energy distribution: too close, and the laser may overheat or damage the material; too far, and the mark becomes faint or indistinct. Auto focus prevents such issues, reducing scrap rates and avoiding unnecessary wear on the laser source or optical components. -

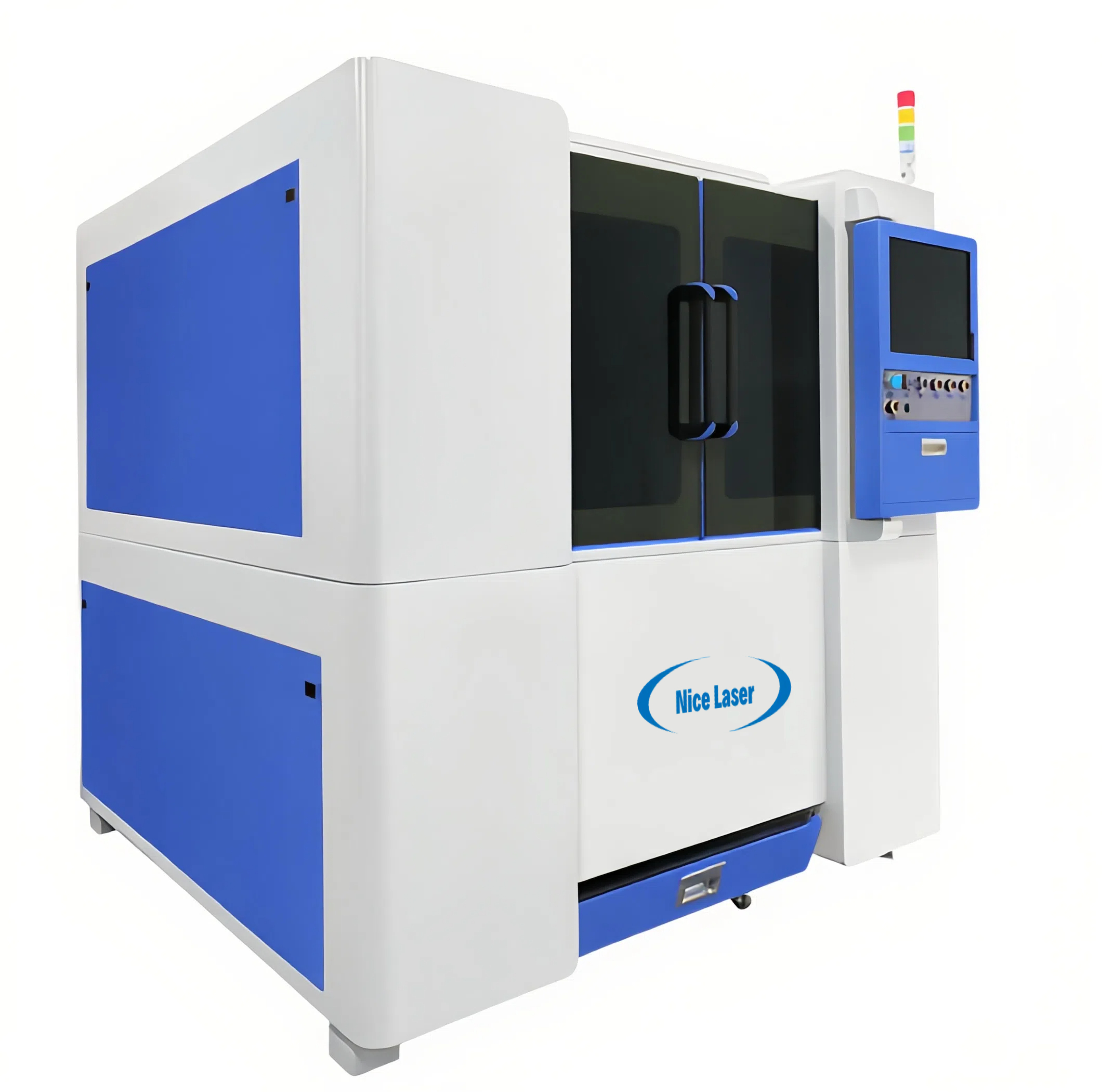

Seamless Integration

with Automation

Auto focus systems easily integrate with robotic arms, conveyor belts, or vision-guided systems, enabling fully automated marking workflows. This compatibility is vital for smart manufacturing environments, where minimal human intervention and data-driven process control are priorities.

In summary, auto focus transforms laser marking into a more reliable, efficient, and flexible process, making it indispensable for modern industrial manufacturing where precision, speed, and adaptability are critical.

Relevant News