The technical advantages of laser welding machine in welding medical cardiovascular stents

Upload Time:

Jul 14, 2025

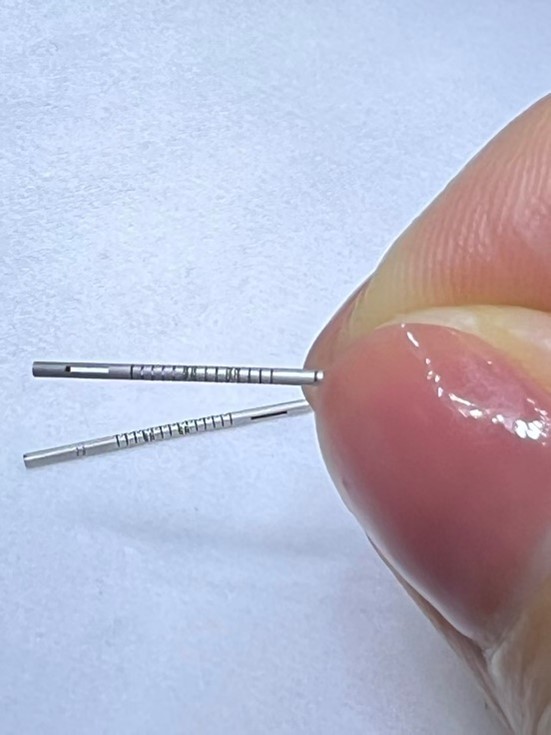

Medical cardiovascular stents are usually made of metal materials such as stainless steel and titanium alloys, which have good biocompatibility and mechanical properties. The laser welding machine is able to weld these materials with precision, ensuring the strength and stability of the stent

The technical advantages of laser welding machine in welding medical cardiovascular stents

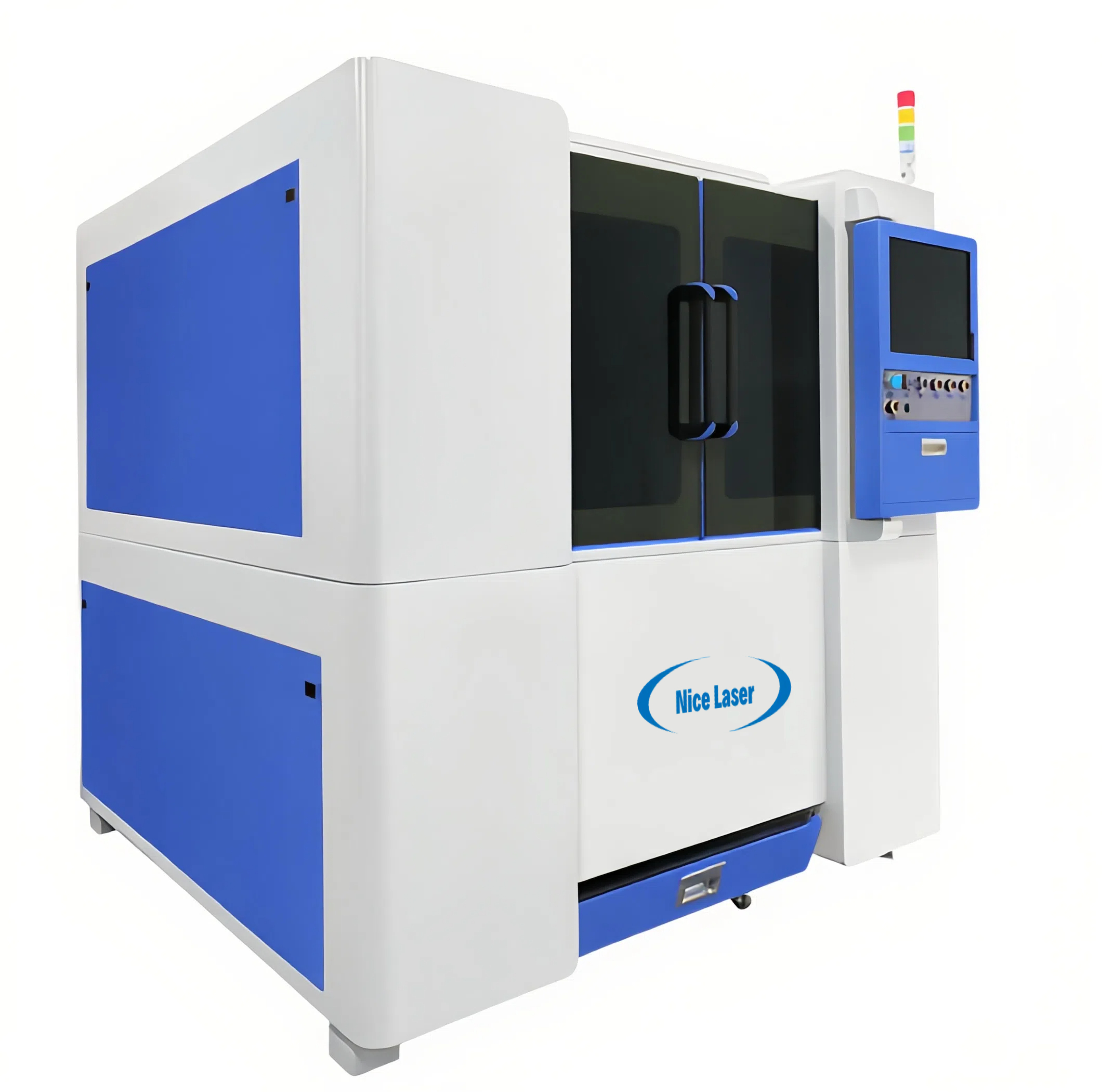

Medical cardiovascular stents are usually made of metal materials such as stainless steel and titanium alloys, which have good biocompatibility and mechanical properties. The laser welding machine is able to weld these materials with precision, ensuring the strength and stability of the stent. The laser welding machine has indeed demonstrated its excellent performance and advantages in the process application of welding medical cardiovascular stents. Let's take a look at the technical advantages of laser welding machines in welding medical cardiovascular stents. The laser welding machine can realize the precise control of the weld, ensure the flatness and smoothness of the weld, and meet the requirements of strength and durability of medical cardiovascular stents. Laser welding technology can effectively ensure the structural integrity of the bracket and avoid performance degradation or failure caused by improper welding. Technical advantages of laser welding machine in welding medical cardiovascular stents: 1. High precision: Laser welding technology can achieve micron-level welding accuracy and high repeat positioning accuracy like 0.02mm, which meets the needs of high-precision manufacturing of medical cardiovascular stents. 2. High quality: This technology has a large welding depth-width ratio, energy concentration and small heat-affected zone, so as to ensure that the quality and position of the welding point meet the design requirements and solve the welding quality difficulties of medical devices. 3. Automation and continuity: The laser welding machine can realize automatic and continuous welding operations in the manufacturing process of medical cardiovascular stents, which improves the production efficiency. 4. Heat control: The heat generated during the welding process is small, and the heat affected zone on the bracket material is also small, which is conducive to maintaining the original performance of the bracket. 5. Environmental protection and cleanliness: There is almost no welding slag and debris in the laser welding process, no need to add any adhesive, and the entire welding work can be completed in the clean room to meet the clean requirements of medical device product welding. 6. Real-time monitoring: The equipment is equipped with an industrial CCD monitoring system, which can monitor the product clamping process and welding process in real time to ensure welding quality and efficiency. 7. Safety: The equipment adopts a structural sealing design, and the power part is sunk to effectively protect the safety of operators. At the same time, all materials used in the equipment have undergone strict testing to ensure the anti-pollution requirements of the high-clean production site of medical devices.

The above is the technical advantages of laser welding machine in welding medical cardiovascular stents, laser welding machine has significant advantages in the process application of welding medical cardiovascular stents, and its characteristics of high precision, high quality, environmental protection and cleanliness, real-time monitoring and safety make it an ideal choice for medical cardiovascular stent manufacturing. With the continuous progress of technology and the continuous expansion of application fields, it is believed that laser welding machines will play a more important role in the medical industry.

Relevant News