The Advantages and Disadvantages of Laser Cleaning

Upload Time:

May 27, 2025

Laser cleaning is a non-contact surface treatment technology that utilizes the interaction between laser beams and materials to remove contaminants, coatings, or oxides.

Laser cleaning is a modern surface treatment technology that uses laser beams to remove contaminants, coatings, or oxides from material surfaces. Here’s a detailed analysis of its advantages and disadvantages:

Advantages of Laser Cleaning

- Non-Destructive and Precise

- Laser cleaning is highly selective, targeting only contaminants while leaving the underlying material intact. This is critical for delicate surfaces (e.g., historic artifacts, aerospace components).

- Example: Removing rust from thin metal sheets without damaging the substrate.

- Environmentally Friendly

- No chemicals, abrasives, or water are used, reducing waste and environmental impact.

- Eliminates the need for post-cleaning disposal of hazardous materials, making it compliant with strict environmental regulations.

- High Efficiency and Speed

- Laser systems can operate at high speeds, especially for large-area cleaning or repetitive tasks (e.g., automotive part preprocessing).

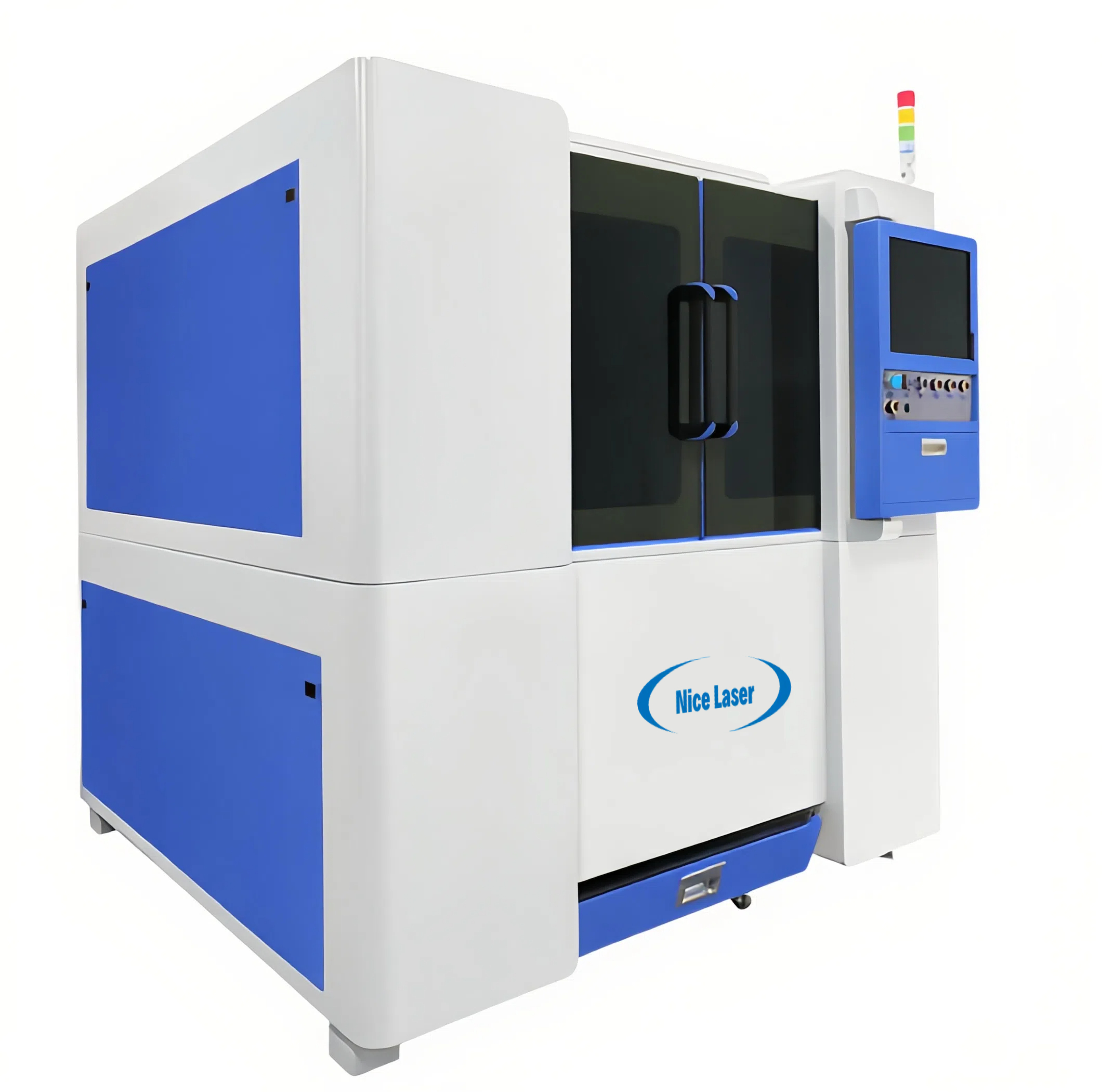

- Automated laser systems further enhance productivity in industrial settings.

- Versatility

- Effective on various materials (metal, plastic, wood, stone) and contaminants (rust, paint, oil, oxide layers).

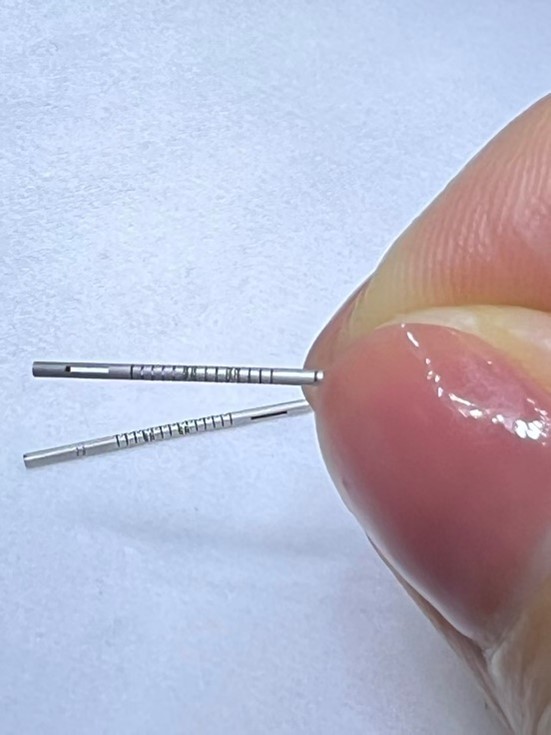

- Suitable for complex geometries and hard-to-reach areas (e.g., intricate machinery parts).

- Minimal Surface Damage

- Unlike sandblasting or chemical cleaning, laser cleaning avoids mechanical abrasion or chemical corrosion, preserving the material’s surface finish and properties.

Disadvantages of Laser Cleaning

- High Initial Cost

- Purchasing laser systems (especially high-power industrial models) is expensive, requiring significant upfront investment.

- Additional costs may include specialized training for operators and safety infrastructure (e.g., protective enclosures).

- Material and Contaminant Limitations

- Some materials (e.g., highly heat-sensitive plastics) may be damaged by laser energy if parameters are not precisely controlled.

- Thick or deeply embedded contaminants (e.g., heavy-scale rust) may require multiple passes or higher power, increasing processing time.

- Safety Concerns

- Laser beams pose risks to human eyes and skin, requiring strict safety protocols (e.g., protective gear, enclosed workspaces).

- Fumes or particles released during cleaning (e.g., vaporized paint) may contain hazardous substances, necessitating air filtration systems.

Applications and Considerations

- Ideal for: Precision industries (aerospace, electronics), heritage restoration, automotive manufacturing, and delicate surface preparation.

In summary, laser cleaning offers unmatched precision and environmental benefits but is best justified in applications where quality, safety, and material preservation outweigh the initial investment and operational constraints.

Relevant News