Laser Welding VS TIG Welding

Upload Time:

May 26, 2025

Laser welding and TIG welding both have their own welding fields. They can be used for different applications according to the industry requirement

Here’s a concise comparison of the advantages and disadvantages of laser welding versus TIG welding, based on their key characteristics and applications:

Laser Welding: Advantages

- High Speed & Efficiency

- Welding speeds can reach several meters per minute, ideal for mass production (e.g., automotive assembly lines).

- Reduces cycle time significantly compared to TIG.

- Minimal Heat Input & Deformation

- Extremely concentrated laser beam creates a narrow heat-affected zone (HAZ) and minimal distortion.

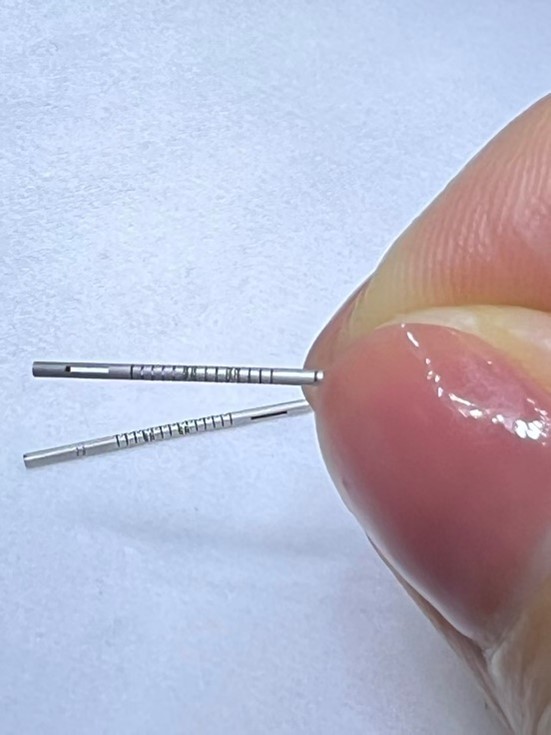

- Suitable for delicate components (e.g., electronics, medical devices) and thin materials.

- Precision & Consistency

- Non-contact process (no physical contact with the workpiece) enables high positional accuracy (micron-level precision).

- Consistent weld quality with minimal human error, ideal for automated systems.

- Deep Penetration (High Aspect Ratio)

- Capable of deep welds with a narrow width (e.g., 10:1 depth-to-width ratio in steel), reducing the need for multiple passes.

- Versatility with Diverse Materials

- Can weld high-melting-point metals (titanium, nickel alloys) and dissimilar metals (e.g., steel to copper).

- Less affected by magnetic fields compared to arc-based processes like TIG.

- Reduced Post-Processing

- Smooth, uniform weld beads often require no grinding or finishing, saving time and cost.

Laser Welding: Disadvantages

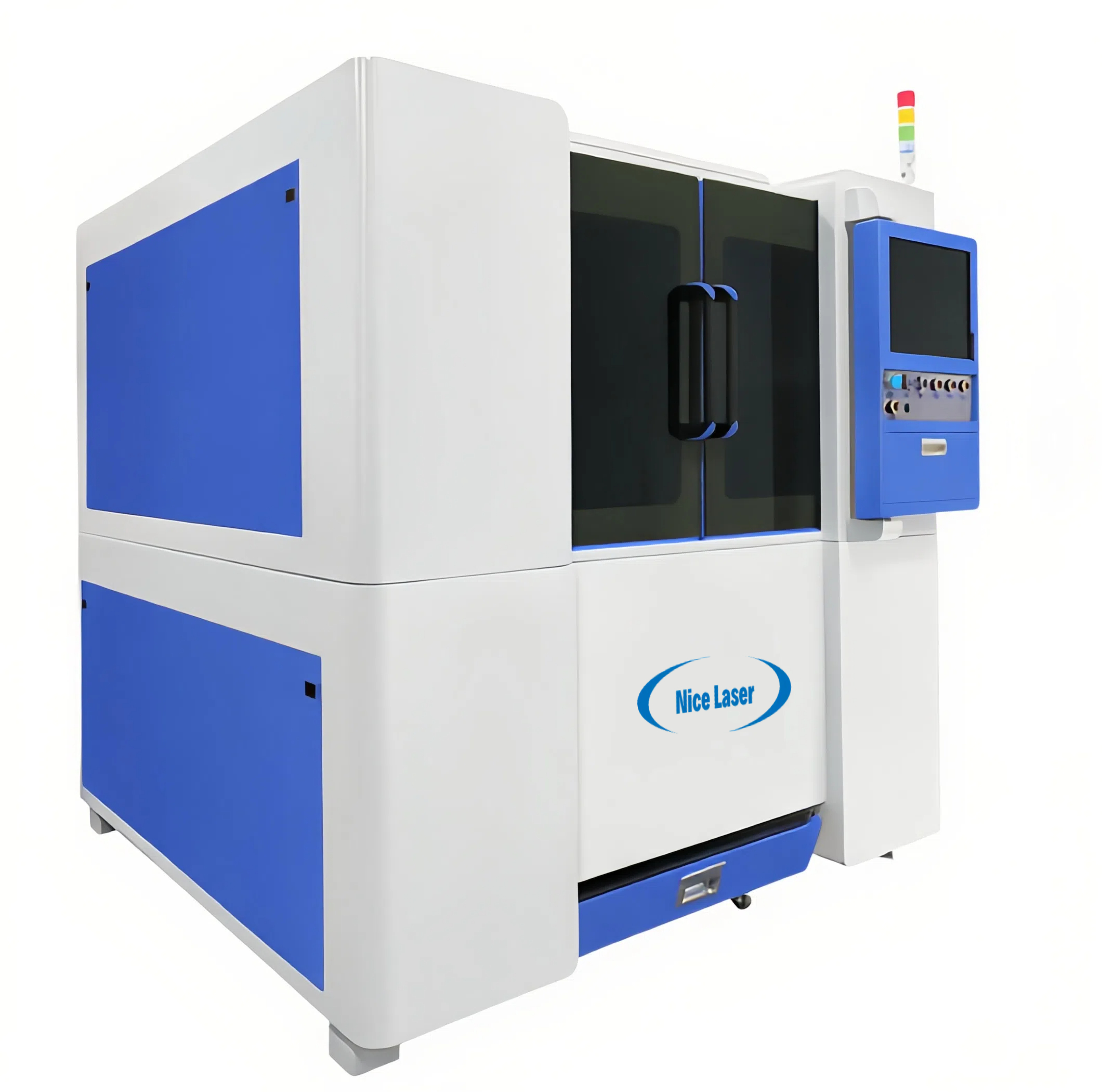

- High Initial Costs

- Expensive equipment (laser generators, optical systems, and automation setups) makes it unsuitable for small-scale or low-budget operations.

- Strict Tolerance Requirements

- Requires precise joint alignment (e.g., gap tolerance <0.1mm) and surface preparation. Misalignment can lead to incomplete penetration or defects.

- Limited Thickness for Some Lasers

- Low-to-medium power lasers (e.g., <2 kW) struggle with thick materials (>5 mm). High-power lasers (10+ kW) are needed for heavy-duty applications, increasing costs.

- Reflectivity Challenges

- Highly reflective materials (e.g., aluminum, copper, gold) can deflect or absorb less laser energy, requiring higher power or specialized techniques (e.g., pulsed lasers).

- Maintenance & Technical Expertise

- Complex optical systems require regular maintenance. Operators need specialized training to optimize parameters (power, speed, focus).

- Limited Accessibility for Complex Geometries

- Line-of-sight is required, making it difficult to weld hard-to-reach or irregularly shaped joints (e.g., deep cavities).

TIG Welding: Advantages

- Flexibility & Handicraft Control

- Ideal for manual welding of complex or irregular joints (e.g., curved surfaces, repair work).

- Welder can adjust parameters (arc length, heat, filler metal) in real time for precise control.

- Low Equipment Cost

- Basic TIG machines are far cheaper than laser systems, making them accessible for small shops, hobbyists, or on-site repairs.

- Suitability for Thin & Delicate Materials

- Can weld ultra-thin sheets (<1 mm) with precise arc control, even in non-automated setups.

- No Reflectivity Issues

- Works well with highly reflective metals (aluminum, copper) using AC TIG for oxide removal (e.g., in aluminum welding).

- Wide Material Compatibility

- Versatile for alloys and exotic metals (e.g., tungsten, molybdenum, stainless steel), including those with surface oxides.

- Post-Weld Adjustability

- Easy to repair or rework welds manually, making it suitable for prototyping or custom projects.

TIG Welding: Disadvantages

- Slow Speed & Low Productivity

- Welding speeds are typically 10–50 cm/min, making it inefficient for large-scale production.

- Requires skilled labor, increasing labor costs for high-volume projects.

- Significant Heat Input & Deformation

- Larger HAZ can cause warping in thin materials or complex structures, requiring preheating or post-weld stress relief.

- Skill-Dependent Quality

- Weld quality varies with operator skill (e.g., arc stability, filler metal deposition), leading to inconsistencies in manual processes.

- Need for Filler Material & Gas Shielding

- Most applications require filler wire and inert gas (e.g., argon), adding to material costs and setup time.

- Electrode Contamination Risk

- Tungsten electrodes can accidentally touch the 熔池 (molten pool), causing contamination and defects (e.g., tungsten inclusions).

- Limited Automation Potential

- Less compatible with high-speed automation compared to laser welding, though robotic TIG systems exist (at higher cost).

Key Takeaway: When to Choose Which?

- Laser Welding is best for high-speed, high-precision, automated applications with consistent joint designs (e.g., automotive, electronics).

- TIG Welding is preferred for manual, custom, or repair work, especially with thin materials, exotic metals, or complex geometries.

The choice hinges on production scale, budget, material properties, and required precision. For example, laser welding excels in mass-produced, uniform parts, while TIG remains irreplaceable for artisanal or specialized welding tasks.

Relevant News