Laser Printer VS Inkjet Printer

Upload Time:

May 23, 2025

The advantages and disadvantages of laser printer and inkjet printer

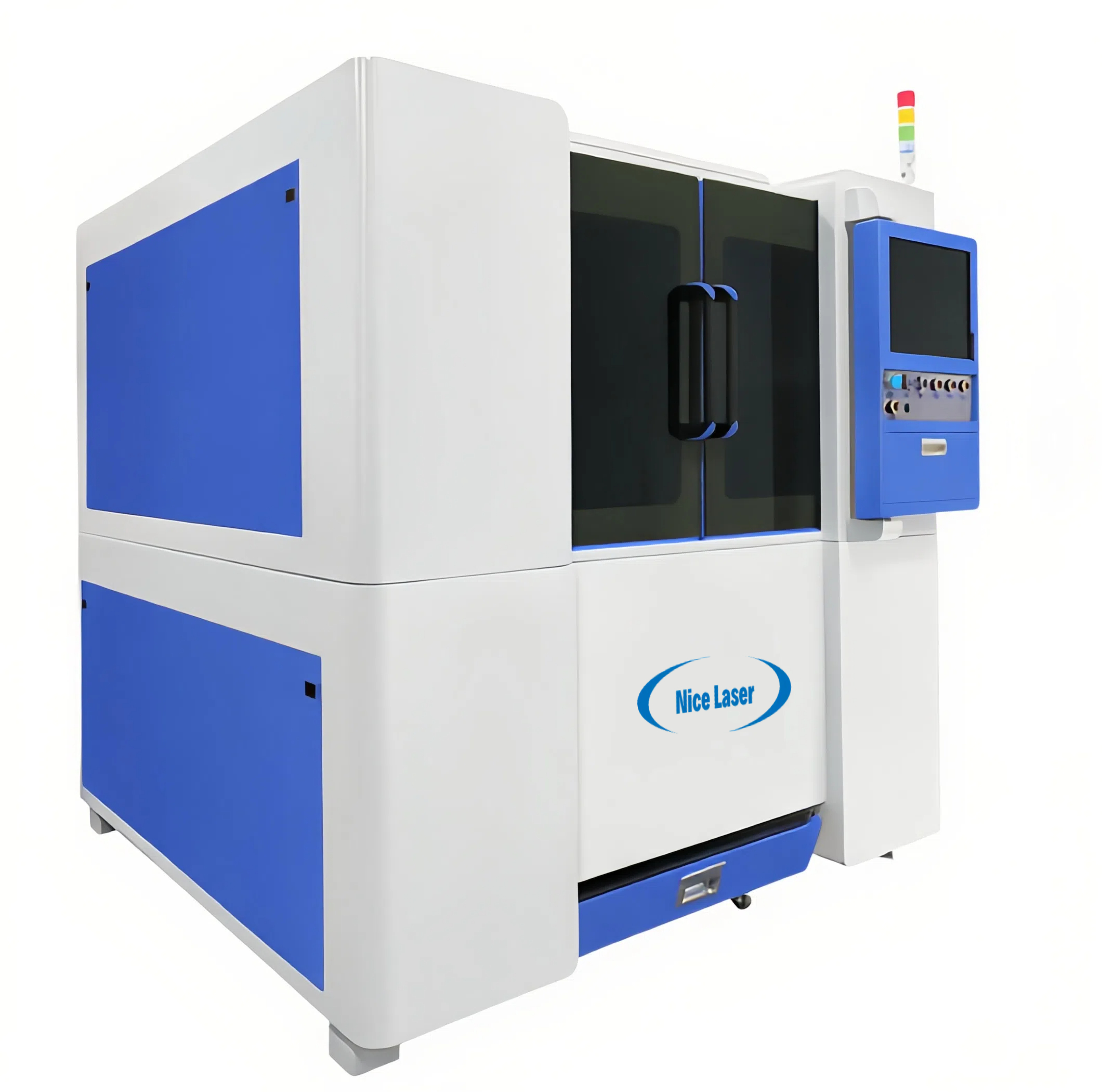

When choosing between a laser coder and an inkjet printer for marking and coding applications, there are several key reasons why laser coders may be preferred. Here’s a detailed comparison highlighting the advantages of laser coders:

1. Durability and Permanence

- Laser Coders:

- Create permanent marks by etching, scorching, or discoloring the surface of the material (e.g., plastic, metal, glass, paper).

- Marks are resistant to abrasion, chemicals, high temperatures, and fading, making them ideal for products that require long-term traceability (e.g., automotive parts, medical devices, industrial components).

- Inkjet Printers:

- Use ink to print marks, which can smudge, fade, or wear off over time, especially in harsh environments (e.g., exposure to water, oils, or friction).

- Requires regular maintenance to prevent ink drying or clogging.

2. Cost-Effectiveness in the Long Run

- Laser Coders:

- Higher upfront investment but no ongoing consumables (e.g., ink, solvents, cartridges), reducing long-term operational costs.

- Free maintenance needs (e.g., occasional lens cleaning or laser module calibration).

- Inkjet Printers:

- Lower initial cost but rely on continuous ink or solvent refills, which can be expensive over time (especially for high-volume production).

- Frequent maintenance (e.g., nozzle cleaning, cartridge replacement) increases labor and downtime costs.

3. Precision and Quality of Marks

- Laser Coders:

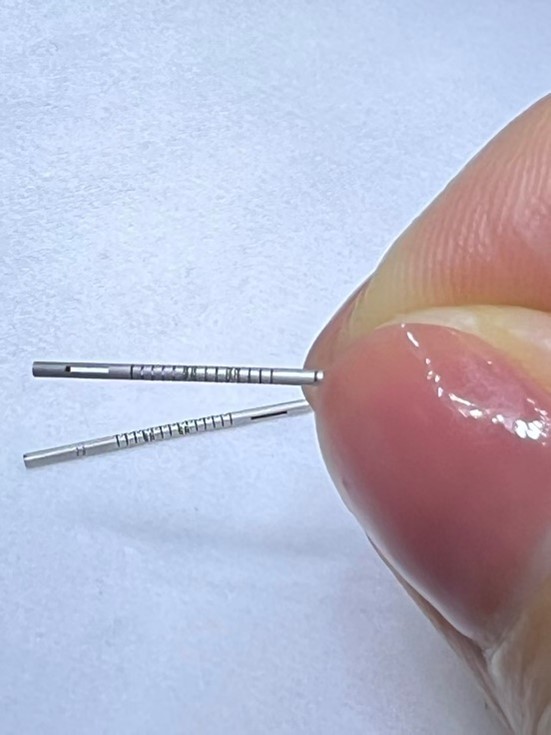

- Achieve extremely high precision (resolution up to 500 DPI or more), allowing for sharp, detailed marks (e.g., tiny barcodes, logos, or alphanumeric text).

- Consistent mark quality without smudging or bleeding, even on irregular or curved surfaces.

- Inkjet Printers:

- Resolution is typically lower (e.g., 100–300 DPI), and ink may bleed on porous materials (e.g., cardboard, untreated plastic).

- Requires careful calibration to avoid smudges, especially at high production speeds.

4. Environmental and Safety Benefits

- Laser Coders:

- Dry marking process with no volatile organic compounds (VOCs) or hazardous waste, making them more environmentally friendly and compliant with strict safety regulations (e.g., food and pharmaceutical industries).

- Reduces the risk of ink spills or contamination in production lines.

- Inkjet Printers:

- Use inks and solvents that may contain VOCs, requiring proper disposal and safety measures to avoid environmental or health hazards.

- Potential for ink leaks or cartridge waste.

5. Speed and Efficiency

- Laser Coders:

- Mark at high speeds (often matching or exceeding inkjet speeds), with no drying time required for the mark.

- Suitable for high-volume production lines where efficiency is critical (e.g., bottling plants, packaging lines).

- Inkjet Printers:

- May require drying time for ink, especially for large or dense marks, which can slow down production.

- Nozzles can block the ink if the printer is inactive for short periods, causing downtime.

6. Material Compatibility

- Laser Coders:

- Work on a wide range of materials, including non-porous surfaces (e.g., metal, glass, coated plastics) and some porous materials (e.g., wood, cardboard).

- Marks can be customized by adjusting laser power and wavelength to suit the material (e.g., CO₂ lasers for organic materials, fiber lasers for metals).

- Inkjet Printers:

- Performance varies by material; porous surfaces (e.g., paper, untreated cardboard) absorb ink well, but non-porous surfaces (e.g., glossy plastics, metal) may require special inks or primers.

7. Regulatory Compliance

- Laser Coders:

- Ideal for industries with strict traceability requirements (e.g., pharmaceuticals, aerospace, electronics), where permanent, tamper-proof marks are mandatory.

- Marks are less likely to fade or become unreadable over the product’s lifecycle, ensuring compliance with standards like FDA or ISO regulations.

- Inkjet Printers:

- May struggle to meet long-term traceability needs due to ink degradation, requiring more frequent re-marking or quality checks.

When to Choose Inkjet Printers?

Inkjet printers still have their uses, such as:

- Low-volume production or occasional marking needs.

- Porous materials (e.g., plain cardboard) where ink adheres well and permanence is not critical.

- Applications requiring frequent color changes (e.g., multi-color logos), as inkjet can use CMYK cartridges.

Conclusion

Laser coders are preferred when permanence, durability, precision, and low long-term costs are essential. They excel in industries like manufacturing, healthcare, and automotive, where marks must withstand harsh conditions and remain legible throughout the product’s lifecycle. Inkjet printers are more suitable for short-term, low-cost, or color-dependent applications. The choice ultimately depends on the specific needs of the production process, material, and regulatory requirements.

Relevant News