Application of Laser Cutting in Medical Stents

Upload Time:

Jan 12, 2026

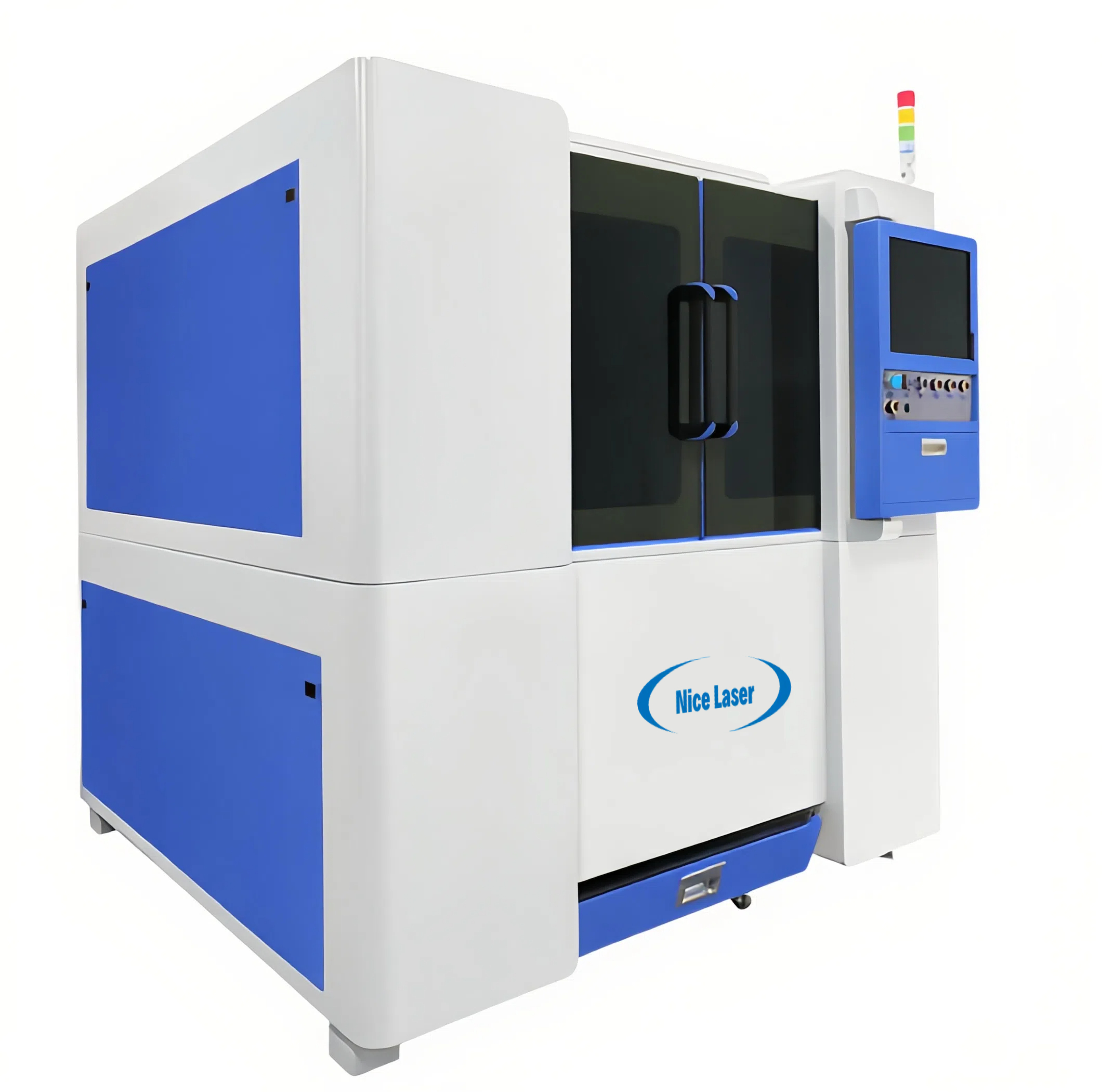

An ultrashort pulse laser cutting machine has been adopted. With pulse widths ranging from 10 picoseconds (10-12 seconds) to hundreds of femtoseconds (10-15 seconds), it allows for near-thermal-free "cold" processing on medical stents

The stent belongs to the third class of medical devices, that is, the highest level of medical devices, it is a slender metal grid, very fine, hollow, cylindrical, mesh metal tube. The principle is to "insert a tiny stent into the blood vessel, stretch the narrowed part open, and maintain smooth blood flow in the lumen."

At present, the stents have a variety of products such as medical stainless steel, nickel-titanium alloy, magnesium-titanium alloy, cobalt-chromium alloy, soluble metal magnesium and biodegradable polymers.

According to the placement site, it can be divided into coronary stents, cerebrovascular stents, renal artery stents, aortic stents, etc.

How are vascular stents processed?

Due to the extremely thin wall tube of the heart stent, the current mainstream stent cutting uses microsecond fiber laser. However, because laser processing itself is thermal processing, the metal is melted with laser and then blown away with high-pressure gas, which will not only leave a lot of slag and burrs after processing, but also the heat during processing can easily oxidize the surface of the bracket to make it brittle, and the residual thermal stress will also cause microcracks and reduce mechanical properties. Moreover, the processed bracket requires a series of post-processing, including cleaning, grinding, pickling, passivation, and finally electrochemical polishing before it can be used.

In recent years, an ultrashort pulse laser cutting machine has been adopted. With pulse widths ranging from 10 picoseconds (10-12 seconds) to hundreds of femtoseconds (10-15 seconds), it allows for near-thermal-free "cold" processing. Unlike the melting mechanism of microsecond lasers, the extremely high peak power brought by the ultra-short pulse width of ultrafast lasers produces multiphoton absorption, which evaporates the material directly by bypassing the melting process. Therefore, ultrafast lasers can process materials with relatively low energy, no residual heat, no residue left on the material, to achieve high-precision and clean processing, can omit many subsequent processes, and has been widely used.

Relevant News