Precautions for Using lasers with Chiller in Winter

Upload Time:

Jan 05, 2026

Recently, due to the widespread cold air across the country, there are some precautions for using lasers with chiller in winter. If the external ambient temperature is too low, the volume expansion after water freezing will cause irreversible damage to the pipelines and optical cables of the equipment water chiller.

Recently, due to the widespread cold air across the country, there are some precautions for using lasers with chiller in winter. If the external ambient temperature is too low, the volume expansion after water freezing will cause irreversible damage to the pipelines and optical cables of the equipment water chiller. Below, we roughly summarizes the key points of laser operation in winter, providing an operational reference for everyone to use lasers better and more reasonably under low temperature conditions. As we all know, the density of ice is less than that of water, and inside the laser, once the cooling water flowing through the core components freezes, the volume will expand, which may lead to serious damage to the pipeline of the laser source, which will seriously affect the safety of the core components, cause significant losses, and even be directly scrapped.

Precautionary Measures

1. Ensure the ambient temperature

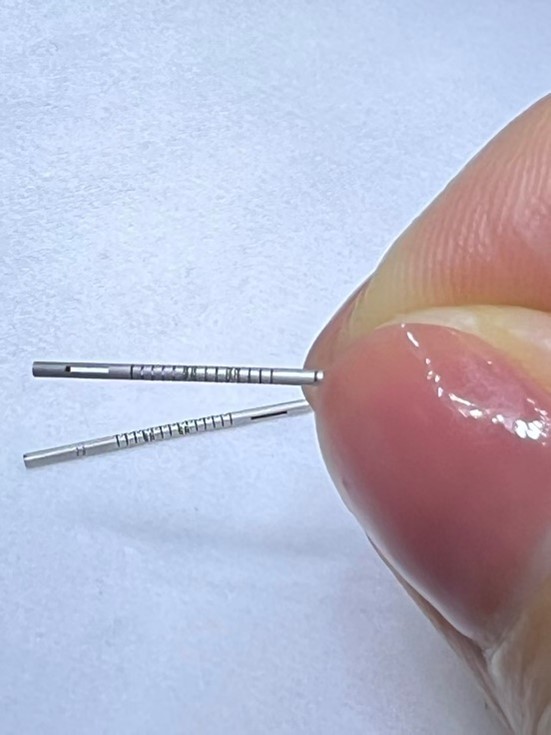

When conditions permit, the use of heating facilities to keep the water chiller and laser in an environment above 5 degrees Celsius. And ensure that these facilities can operate continuously and safely, which can effectively prevent ice formation inside the laser. If the above conditions cannot be met, keep the water cooler on all the time. If the water in the line is constantly flowing, it will prevent freezing. Of course, in this case, if the water cooler is stopped for a long time or there is a power outage due to a fault, there is also a certain risk of freezing. If the laser needs to be downtime, stored or transported for extended periods, it is necessary to ensure that the coolant in the laser line is drained. Clean and oil-free compressed air or nitrogen is blown from the water inlet to effectively drain the residual coolant in the pipeline. The pressure of compressed air or nitrogen needs to be kept within a certain range, and too high pressure will easily cause damage to the pipeline. Some laser water connections use self-locking push-in connectors, please use the original snap-in connectors to open the self-locking device for drainage. If none of the above can be done, add anti-freezer.

02. Selection of anti-freezer

1. Please choose an anti-freezer with a suitable freezing point according to the local temperature. The choice of anti-freezer is not that the lower the freezing point is better, but that according to the local minimum temperature, choose an anti-freezer slightly lower than the local temperature. The addition ratio is 3:7 (30% antifreeze, 70% water). 2. It is recommended to use professional anti-freeze. Well-known brands: DowthemSR-1 products represented by Dow Chemical in the United States or CLARIANT (Clariant) brand are recommended. There are two models of antifreeze suitable for laser systems: 1) Antifrogen®N glycol-water type; 2) Antifrogen®L propylene glycol-water type; Note: Any antifreeze is not replaced for deionized water and is not recommended for long periods of time throughout the year. It is recommended to use deionized or distilled water to clean the pipeline after winter, and resume using deionized or distilled water.

Relevant News