The Advantages of Fiber Laser Cutting Machine

Upload Time:

Jan 05, 2026

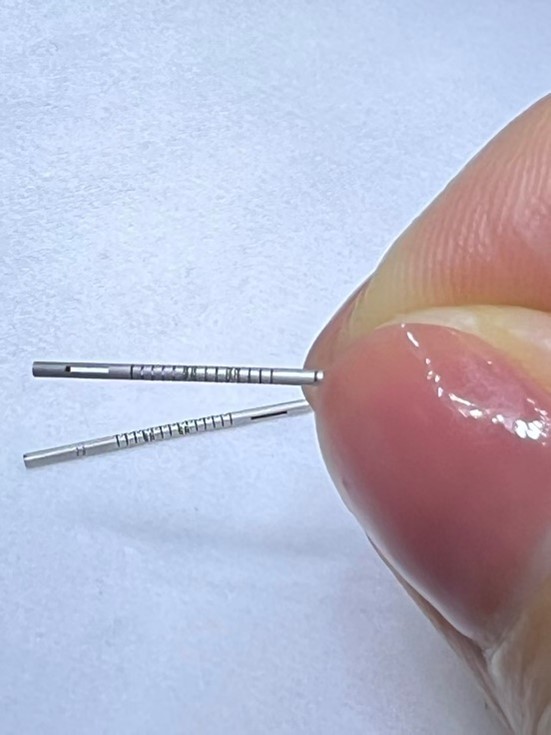

The standard cutting area of the high-precision fiber laser cutting machine is 600mm*600mm. It is primarily designed for high-speed hole cutting and edge trimming of various thin metal sheets under 5mm thick, with a cutting accuracy up to ±0.003mm.

The standard cutting area of the high-precision fiber laser cutting machine is 600mm*600mm. It is primarily designed for high-speed hole cutting and edge trimming of various thin metal sheets under 5mm thick, with a cutting accuracy up to ±0.003mm. Its efficiency is more than twice that of CNC machining, and its subsequent maintenance costs are only 1/3 to 1/4 of those of a comparable CNC punching machine. It is mainly suitable for precision hole cutting or edge trimming of 3C electronic metal materials such as audio panels and metal films; precision cutting of metal eyeglass frames; and cutting of saw blades, spring sheets, silicon steel sheets, and aluminum-magnesium alloy panels.

Laser Equipment Features:

1.Highly adaptable to materials, capable of cutting and processing various irregularly shaped small hardware parts;

2.High production efficiency, capable of replacing traditional manufacturing processes such as CNC punching and shearing and manual processing;

3.Fast cutting speed, no edge collapse, no damage to workpieces, and extremely high yield rate;

High cutting precision, smooth and burr-free cut surface, good perpendicularity, no need for subsequent secondary processing;

4.Simple and quick operation, with an embedded rich process database that can be called or modified with one click;

5.Stable and reliable performance, high efficiency and energy saving, low maintenance costs, and long service life;

6.Customizable to various non-standard models and fully automatic feeding devices, shortening unloading time;

7.Green and environmentally friendly processing, no pollutants generated, no consumables, and high yield rate;

Relevant News