Laser Coding in Medical Instruments

Upload Time:

Jul 02, 2025

Medical instruments coding regulations mainly focus on the unique device identification (UDI) system, aiming to achieve traceability of medical devices.

Medical instruments coding regulations mainly focus on the unique device identification (UDI) system, aiming to achieve traceability of medical devices. Laser coding is an important way to implement these regulations, with specific requirements in terms of code quality, size, and marking location. The following are the details:

Coding Regulations

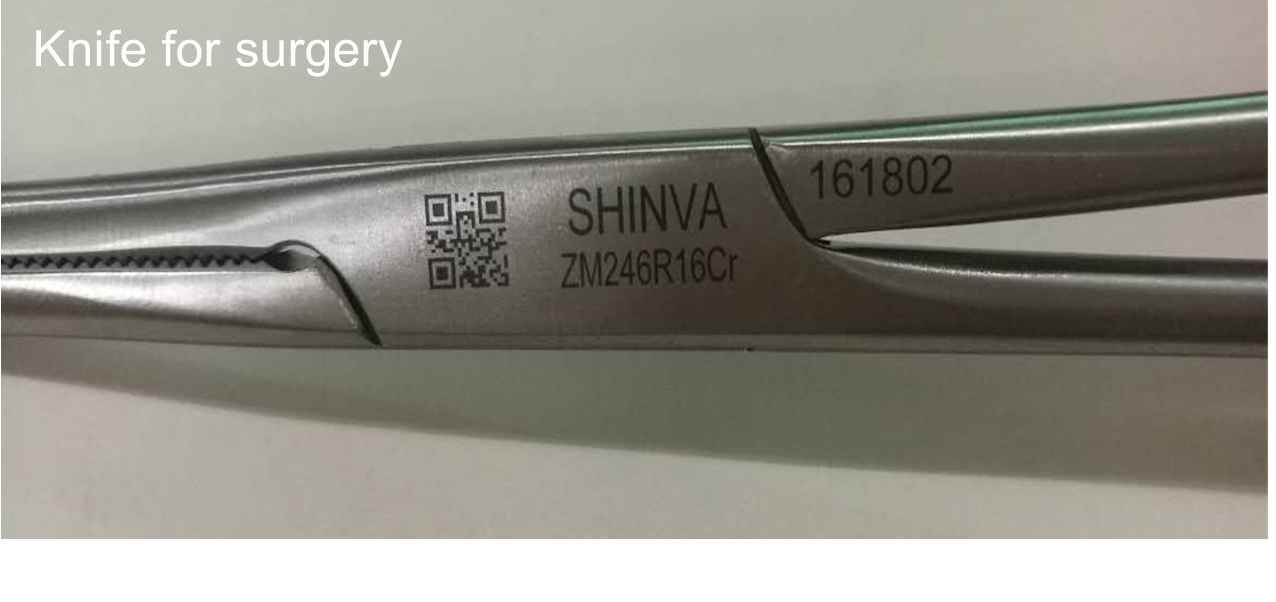

- Chinese Regulations: Based on the Regulations on the Unique Device Identification System for Medical Devices, medical devices should be marked with UDI, which consists of product identification and production identification. The UDI should be marked on the device itself (for reusable products) and all levels of packaging, and be presented in both machine - readable and human - readable formats.

- US Regulations: According to FDA regulations, since September 24, 2022, all reusable and re - processed medical devices sold in the US must have a UDI direct mark, and this requirement has been extended to class I products. The UDI code should include information such as the expiration date, batch number, and serial number.

- EU Regulations: The EU's Medical Device Regulation(MDR) 2017/745 and the In-Vitro Diagnostic Regulation (IVDR) 2017/746 stipulate that each medical device must have a UDI, which should be marked on the device, primary packaging, and subsequent packaging. The UDI is composed of a device identifier (DI) and a production identifier (PI). The EU will gradually implement the UDI marking requirement for all medical devices by 2027 according to the device risk class.

Laser Coding Requirements

- Code Quality: According to FDA guidelines, the quality grade of laser - marked UDI code verification should be at least grade C, and grade B or A is better. This quality level needs to be maintained throughout the product's life cycle, even after multiple re - processing cycles. Techniques such as frosting can be used to improve code readability.

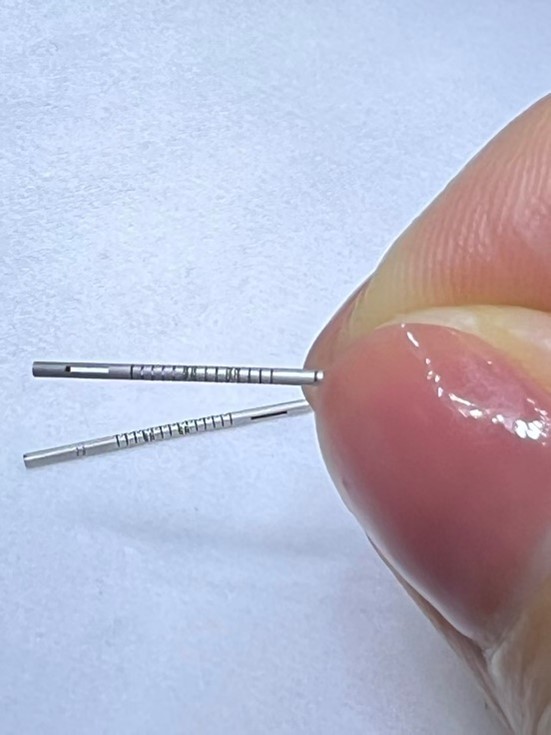

- Code Size: The machine - readable UDI can be in the form of a data matrix or a linear barcode. For laser - marked GS1 - standardized codes, the minimum module size of the data matrix code is 0.1 mm. It is recommended that the data matrix code area be about 2.5 x 2.5 mm or larger to ensure that most verifiers can scan the code.

- Marking Location: According to EU regulations, the UDI needs to be marked on the medical device itself, the primary packaging, and each subsequent packaging. When selecting the laser coding method, factors such as the size of the printable area, the material to be printed, and the application of the medical device should be considered. For example, fiber laser permanent marking is suitable for surgical instruments that need to be sterilized repeatedly.

Material Adaptability: Laser coding has good adaptability to various materials of medical devices. For example, UV laser coding is suitable for medical device packaging made of DuPont™ Tyvek® and other synthetic fiber materials, which can ensure that the code is not easily damaged during the sterilization process. Fiber laser marking systems are commonly used for medical devices containing high - density materials such as metal, aluminum, and stainless steel.

Relevant News