Application of Laser in Food Packaging with Easy Tear Notches

Upload Time:

Jun 16, 2025

The plastic, metal, and paper layers exhibit different absorption and reflection properties in different wavelength ranges of CO2 lasers

The

plastic, metal, and paper layers exhibit different absorption and reflection properties

in different wavelength ranges of CO2 lasers. PET/Aluminum/PE, which is a typical

composite material for food packaging, such as coffee packaging bags. The material's

selective absorption of the CO2 laser at 10.6 wavelengths allows for complete vaporization

of the PET layer in very fine localities without affecting the other layers, and

the reflection effect of the foil layer facilitates a more efficient use of the

laser to achieve the effect of layer cutting. As a laser layer cutting technology

for easy tear technology, it is used in a wide variety of food packaging bags and

daily necessities packaging bags. In these applications, laser technology offers

the following advantages over mechanical methods such as conventional rotary tools:

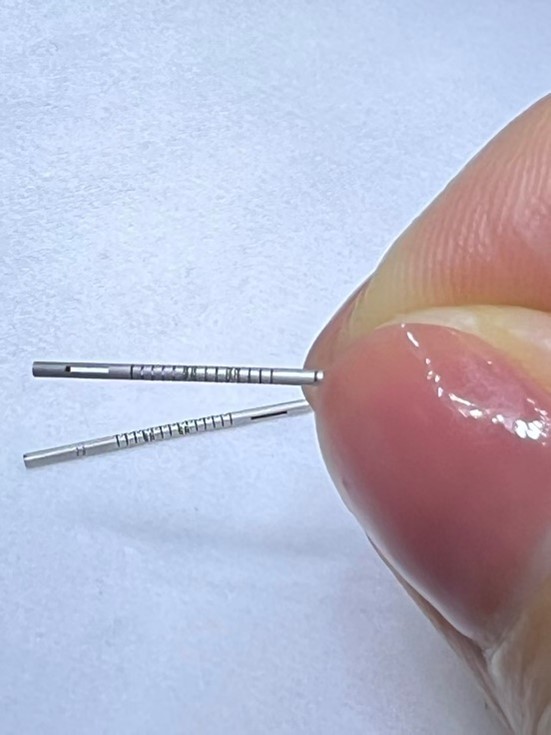

1. The special selectivity of the laser for different film materials makes it possible

to cut a certain film layer without affecting other layers. 2. Different from machining,

there is no contact and wear during laser processing, which ensures the reliability

of the process in the high-speed processing process. 3. Machining needs to change

the film and tools frequently, and it cannot control the direction of the tearing

line after the customer tears, and often cannot tear along the easy-to-tear line

of the product design. The laser technology layer cuts the easy-to-tear line, which

not only does not destroy the packaging function, but also allows the tearing line

to be torn along the easy-to-tear line, and the nicking is basically invisible,

making the packaging design more flexible. Laser scribing technology is a more advanced

and flexible technology that concentrates laser energy on the thin film layer that

needs to be scribed without damaging the entire film. Because composite films such

as PET, PP or PE all have different wavelengths of absorbing and emitting CO2 lasers,

when one layer of film absorbs the laser energy and disappears, the other layers

remain 100% intact and are not affected in any way. On the other hand, the aluminium

foil layer or other thin film coated with a metal layer acts as a barrier to the

laser to other material layers. Therefore, the characteristics of these materials

allow laser technology to accurately locate and scribe on packaging materials. At

the same time, the tear-off line is clearly visible through the human eye, so tearing

the packaging is a breeze for consumers. It is worth noting that laser scribing

technology is a non-contact and wear-free process for food packaging, so it also

ensures that the goods in the package will not be damaged due to the packaging process,

ensuring the stability and reliability of the goods.

Relevant News