The Advantages of 3D Laser Galvo Head Over 2D Galvo Head

Upload Time:

Jun 24, 2025

A 3D laser galvo head offers several advantages over a 2D galvo head due to its ability to control the laser beam in three dimensions (X, Y, and Z axes) rather than just two (X and Y).

A 3D laser galvo head offers several advantages over a 2D galvo head due to its ability to control the laser beam in three dimensions (X, Y, and Z axes) rather than just two (X and Y). Here are the key benefits:

1. Depth Control (Z-Axis Movement)

• A 3D galvo head integrates dynamic focus control (often via an additional Z-axis motor or liquid lens), allowing it to adjust the focal plane in real time.

• This enables non-planar processing, meaning the laser can maintain focus on curved or uneven surfaces without mechanical Z-axis movement.

2. Faster Processing on Complex Geometries

• Unlike a 2D galvo, which requires mechanical Z-axis movement (slowing down the process), a 3D galvo can dynamically adjust focus at high speeds.

• Ideal for 3D engraving, curved surfaces, and variable-depth machining.

3. Improved Precision on Uneven Surfaces

• A 2D galvo loses focus if the workpiece is not perfectly flat, leading to inconsistent results.

• A 3D galvo compensates for height variations, ensuring consistent spot size and energy density across the surface.

4. Reduced Need for Mechanical Movement

• With a 2D galvo, large Z-axis adjustments require moving the workpiece or laser head mechanically (slower and less precise).

• A 3D galvo adjusts focus electronically, reducing reliance on mechanical stages.

5. Better Suited for 3D Printing & Additive Manufacturing

• 3D galvo systems are used in laser powder bed fusion (LPBF) and other additive manufacturing processes where precise Z-axis control is critical.

6. Enhanced Flexibility in Applications

• 3D galvo heads are ideal for:

o 3D laser engraving (e.g., curved molds, automotive parts)

o Laser welding on uneven surfaces

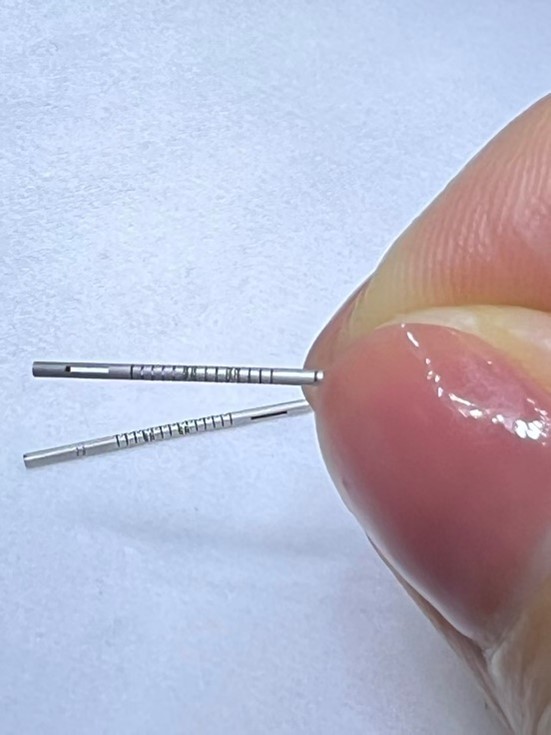

o Micro-machining with variable depth

o Medical device manufacturing (e.g., stents, implants)

7. Higher Throughput in Multi-Layer Processing

• Since the 3D galvo can rapidly adjust focus, it can process multiple layers without stopping, improving efficiency in multi-depth applications.

Limitations of 2D Galvo Heads

• Restricted to flat or pre-focused surfaces.

• Requires mechanical Z-axis movement, slowing down operations.

• Less effective for complex 3D geometries.

Conclusion

A 3D laser galvo head is superior when working with 3D surfaces, variable depths, or high-speed precision applications, while a 2D galvo head is sufficient only for flat or pre-focused laser operations. The choice depends on the specific application requirements.

Relevant News