Laser black marking in medical devices: permanent high-contrast marking of stainless steel and aluminum

Upload Time:

May 30, 2025

Laser marking is non-contact processing, no damage to the processed materials, non-toxic, high environmental protection, flexible marking content, permanent marking and other characteristics, especially in the medical device industry has inherent advantages.

Laser Black Marking in Medical Devices: Permanent High-Contrast Marking of Stainless Steel and Aluminum

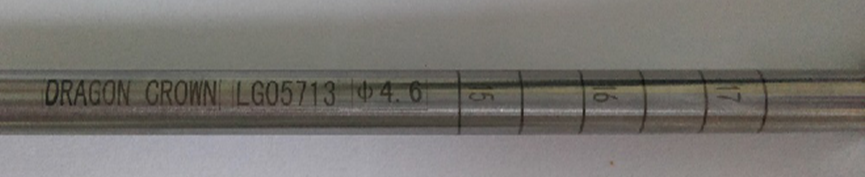

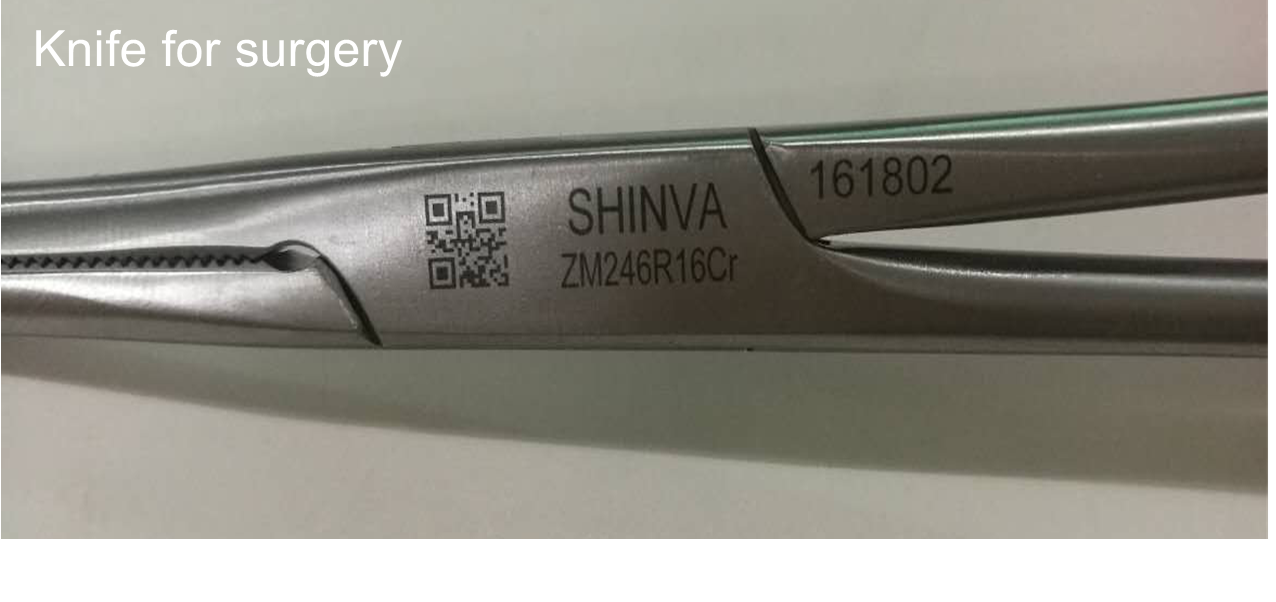

In 2015, the U.S. Food and Drug Administration (FDA) implemented medical product identification regulations, requiring all products and devices to have a unique device identifier (UDI), that is, drugs and parts of medical devices are required to be marked with identification codes. UDI should have the following criteria:

1. High contrast and deep blacks;

2. Permanent, non-fading, corrosion-resistant;

3. Machine-readable;

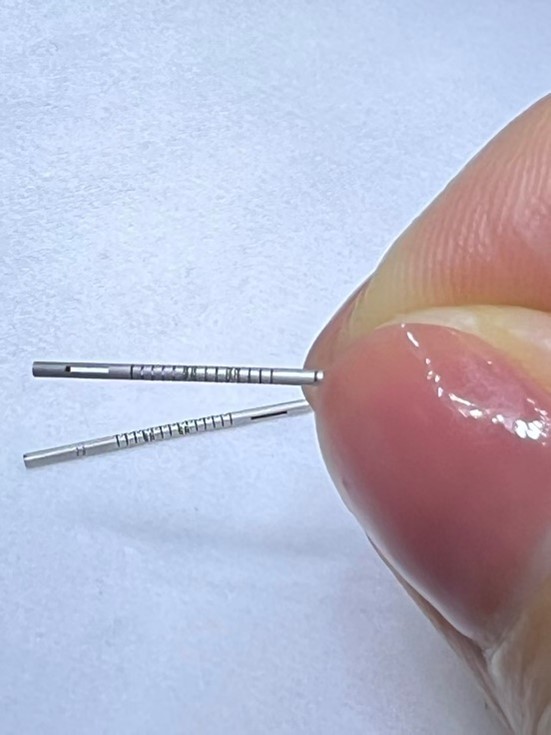

4. Shallow marking, with little surface undulation, prevents bacterial aggregation.

Ordinary markings can often be damaged or detached, such as contamination from ink markings, and most importantly, these unique markings must have a high enough contrast that they will not be damaged by repeated sterilization, and black marking creates high-contrast markings, which are ideal for reusable medical supplies. Laser marking is non-contact processing, no damage to the processed materials, non-toxic, high environmental protection, flexible marking content, permanent marking and other characteristics, especially in the medical device industry has inherent advantages.

Relevant News