How to Select the Correct Laser Cleaner between pulse laser cleaner and CW laser cleaner

Upload Time:

May 29, 2025

Laser cleaning is the lastest laser technology for the automobile & mold industry

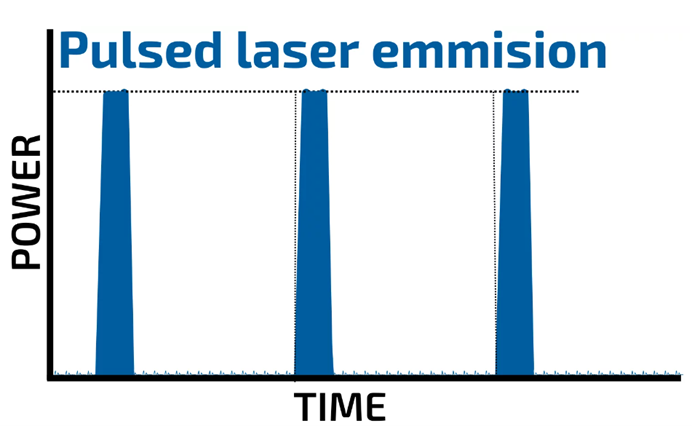

Pulsed

lasers emit flashes of light at a time interval.

– The laser does not emit any radiation between pulses.

– The period is the time from the start of one pulse to the next.

– Pulse duration (pulse width) is the time measured during the pulse, often at its full width and half maximum (FWHM).

Pulsed lasers emit pulses of radiation at a time interval. There is no emission between pulses.

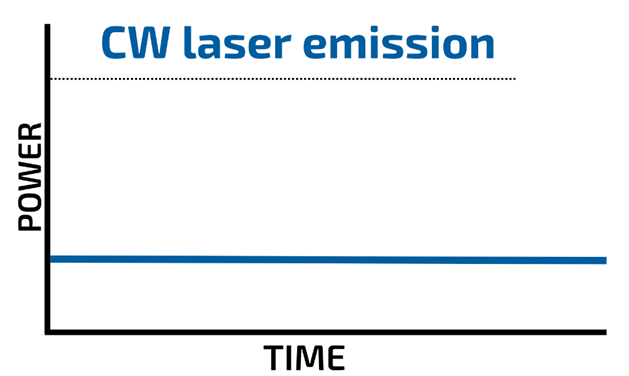

Continuous

wave (CW) lasers provide steady emission.

– Peak, minimum and average performance are approximately the same.

– Significantly greater heating of the material to be cleaned, which can cause

damage.

– Period and pulse width do not apply unless the light is modulated.

Continuous wave (CW) lasers emit radiation whose optical power is approximately constant with time.

What is peak laser power and what role does laser frequency play in cleaning?

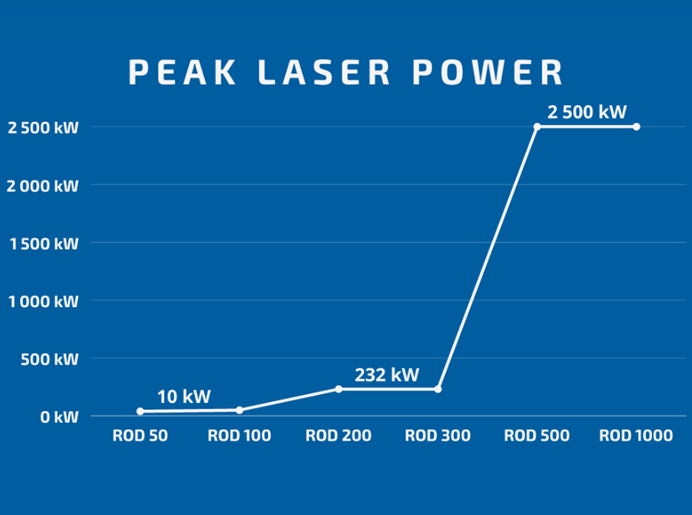

Peak power means (as opposed to average or medium power) the power within one pulse, or if you prefer, the mean power of one pulse. The product of the pulse duration and the peak power gives the pulse energy.

The repetition rate is then a quantity that indicates the number of repetitions of a periodic event for a given period of time – for a laser it means the number of pulse repetitions per 1 second. Our systems have an adjustable frequency from 5 to 200kHz, i.e. 5000 to 200000 pulses per second. The frequency can be compared to the engine of a vehicle for ease of understanding. For optimum engine function without damaging the engine, you always keep it at a certain appropriate speed. For the most effective cleaning effect without damaging the material to be cleaned, the correct repetition rate must also be used.

Conclusion

- Pulse laser cleaners are preferred for precision, delicacy, and heat-sensitive applications, where controlled energy delivery is critical.

- CW laser cleaners are ideal for high-power, continuous, and heavy-duty cleaning tasks where heat tolerance is high.

Relevant News